Al2O3 is one of the primary constituent of Type I glass, commonly used in pharmaceutical glass container manufacturing. The presence of Al2O3 in the glass formulation has a double impact: as glass network former (together with SiO2 is a part of “refractory constituents”) and as network stabilizer giving to Al2O3 containing glass higher chemical resistance lowering the alkaline release.

Clearly Al2O3 is a necessary constituent in the so called “Alumino-Borosilicate glass”, and as Biavati et al (1) showed, Type I glass may produce a sensible release of Al ions in specific conditions. This tendency can subsequently produce a variety of chemical interactions between released Al3+ and constituents of contained drugs that can evolve in complete API degeneration catalyzed by amphoteric nature of Aluminum Ions, depending on the solution pH.

One of interesting API is the Epinephrine / Adrenaline commonly used in combination with Lydocaine in dental anesthetics. Studies on factors that could affect the degradation of Epinephrine stored in glass container do not give relevant results regarding the role of Al (III) released from the inner surface of glass container(2)(3), but periodical checks of control samples stored showed how Epinephrine effects has been strongly reduced also after months, already with 0,5 ppm of Al in solution: the result is a sensible reduction of anesthetic shelf life (around 1/3) linked to high costs and loss of market appeal.

There are factors that can mitigate glass chemical release and Al as well, such as a correct forming/converting process of the glass and the washing of container before filling.

As long as Al release from converted tubular glass containers is concerned, it has been found that one of the crucial parameter that was not usually considered, is the tubular glass manufacturing process and consequently, the materials the molten glass came in contact with.

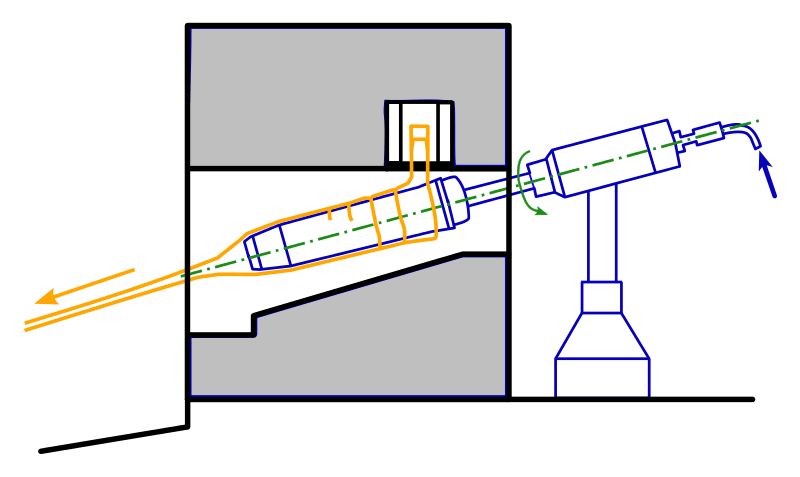

In Danner process, the tubing forming is obtained rolling a glass flow on a rotating sleeve generally made in refractory materials such as high Zirconia and/or high Alumina content ones.

The more advanced technologies, improved the production process in terms of glass quality by using a surface coated sleeve (metalized with Noble metals). Comparing different tubular glass containers obtained in different ways, a model based on Thin film Theory has been hypothesized and than confirmed by experimental data, to explain differences in terms of Al release between coated and uncoated refractory sleeve used.

In particular, the experimental data collected showed that during glass tubing productionit is reasonable to presume, a thin film formation at interface between molten glass that flow over and the refractory sleeve that is rotating underneath (SEM analysis of glass/sleeve interface and EDS analysis of refractory section at various distance from interface shown a distance based Al concentration gradient).

This thin film resulted enriched in Na and in Al, the first moving from the glass where is the more mobile specie which occupy the free space in the glass network, the second moving from the sleeve surface: the driving force in both cases is the concentration gradient (Fick Laws) and the mechanical and thermal aggression made by glass to the refractory surface. Considering the commonType I glassand refractories composition (Al2O3 content is around 5-7 %in the glass and up to 60% in High Al content refractories), it appears clear how the Al migration could create a time based porosity of the sleeve surface that increase the aggression rate. The Alumina migrated from refractory to the glass, tends to occupy the free space present in the structure (considering the relative low viscosity of the glass at the forming point ≈10 4 poise), instead to link with existent network (4). The result is the formation of a thin glass film enriched in very mobile Na and Al that sliding on the sleeve, that concur to originate the inner surface of glass tubing and consequently of the glass container in contact with the contained solution.

The so produced glass tubing shows a higher Na release and, in time, Al release.

The implementation of a metal (noble) coated sleeve technology, is effective not only in terms of Na release (strongly demonstrated by experience) but also for what concern Al release, avoiding the formation of the over mentioned contact between glass and refractory as is and the Al migration at interface.

Comaprison test, made on tubing glass container obtained with coated sleeve, showed a reduction close to90% in terms of Al release.

By the overmentioned consideration it is reasonable to expect that the Glass Tubing production technology commonly known as “Vello”, based on static metallic (metalized) sleeve (no refractory/glass interface at the inner tube surface formation), can give the best performances in terms of Al release and containers obtained from over mentioned tubes could guarantee a long term stability of contained Epinephrine.

(1) Alberto Biavati; Paolo Amadei – “Significance of Aluminium Release from Type I Borosilicate Glass Containers” – Pharmind 2010.pdf

(2) David Stepensky; Michael Chorny; Ziad Dabour; Ilana Schumacher – “Long-term Stability Study of L-Adrenaline Injections: Kinetics of Sulphonation and Racemization Pathways of Drugs Degradation”pdf

(3) O’Conceanainn M; Hines MJ – “The kinetics and mechanism of the reactions of aluminium (III) with gallic acid, gallic acid methyl ester and adrenaline” – J Inorg Biochem, 2001 Mar; 84 (1-2) : 1-12

(4) M. Balconi“Esperienze di attacco sui silicati di alluminio” – Rend. Soc. Min. It. – vol.1, pag. 236

One thought on “How tubular glass manufacturing process can affect the final product stability and technological improvement to mitigate it. Al – Epinephrine interaction: a related example.”