As described in the previous so called article “How tubular glass manufacturing process can affect the final product stability and technological improvement to mitigate it. Al – Epinephrine interaction: a related example. ” the Aluminum release from inner surface of glass containers become a key factor when the shelf life (or activity) of the contained API results to be highly sensible to Aluminum concentration, and in many cases, the release of this element could be dramatically correlated to the glass tubing manufacturing process. To be able to discriminate which glass manufacturing process might guarantee the best performances, it is necessary to define a strong enough analytical protocol (routine) which start from sample selection, sample preparation and correct manipulation (to avoid any unwanted contamination), passing through the definition of correct analytical set point (reagents, temperatures & times, instrument choice) until to definition of evaluation grid with limits and acceptability range.

In general, to obtain an effective analytical method optimization, it is necessary to define a correct Design Of Experiment (DOE) considering all the possible direct variables that could affect the results or performance is going to be investigated, and how many levels for each variable I think to investigate (reasonably based on experience and knowledge of process variability); result will be a Matrix of experiment which gives the number of trials needed.

The described methodology, voluntarily reported only as a general overview and not as detailed procedure, has been developed after testing different sets of glass tubing, produced with 3 different manufacturing processes (Vello, Coated Danner, Uncoated Danner) and the respective sets of cartridges, performing analysis with different analytical equipment and different extractable solutions (more than 180 different samples analysed). Conditions set up in order to simulate the aging and consequently to promote the release in acceptable time, involved the sterilizing cycle, performed by using an autoclave in the following conditions: 60 min, 121 +/- 1 °C, 1 bar, commonly used to test the Hydrolytic Resistance of Glass Containers (Eu.Ph. 3.2.1).

Faced critical factors are:

– The addition of concentrate acid to the extract solution in order to stabilize the signal along the time.

– Pre-handling of reusable tools and equipment (for silicone stoppers and auxiliary glassware must be preventively autoclaved for at least 3 times) to avoid undesired contamination.

Reagents and tools (minimum requirements)

- Autoclave with temperature control and certified logger, able to perform Eu. Ph. Sterilization cycle as following described: 60 min; 121+/- 1 °C; 1 bar

- Water R1 as per Eu.Ph. definition.

- AAS with Al dedicated lamp (ICP techniques also investigated)

- Water solution of EDTA (500 ppm chosen)

- Stoppers for Glass dental cartridges

- Concentrate Acid (Acetic preferred)

Tools pre handling

Tools and glass equipment that will be in contact with extraction solution have to be washed and rinsed with Water R1 and consequently autoclaved for 3 times, under Eu.Ph. conditions.

Sample preparation and manipulation

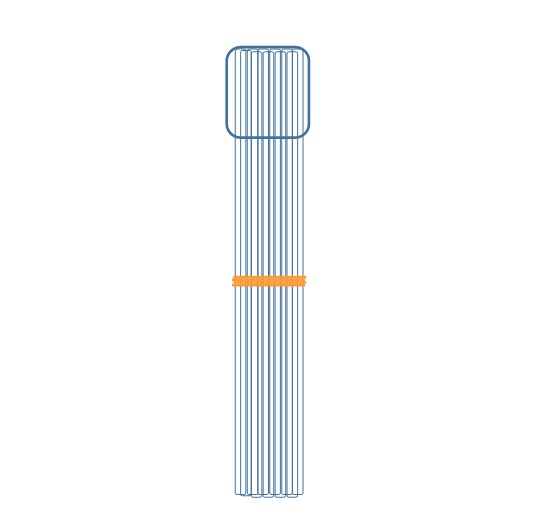

- Glass Tubings: from each glass tubing obtain 2 samples, of approx. 440 mm length, bottoming on end by using a medium flame to avoid high transforming stress in the glass. Wash samples as per Eu.Ph. and fill with EDTA Solution up to 20 mm under the neck. Group sticks with rubber ring and cover with glass beaker, identifying different samples.

- Glass cartridges: select randomly from an adequate number of cartridges, close the bottom with appropriate 3-times autoclaved stopper and wash as per Eu.Ph. and fill with EDTA solution. With pencil identify the sample writing on the beaker external surface, cover the beaker with glass stopper (plate).

Once the autoclave is filled with samples, introduce data logger and start sterilizing cycle. At the end of the process, open the autoclave and let sample cooling at natural rate.

- Glass Tubing: collect 10 ml of extract from each tube in a separate glass beaker, add some drops of Acetic Acid and analyze by AAS.

- Glass cartridges: collect 10 ml from the set of cartridges, add some drops of Acetic Acid and analyze by AAS.

An appropriate calibrations sets of standards have to be put in place, in the same manner of final sample considering also the acid addition.

Limits

The obtained results of experimental routine identified a realistic limit of Al concentration leached, valid for AAS and specially for ICP technique, which allow to discriminate among different glass tubing manufacturing processes.

Based on experimental data and repeated tests, the inner surface leaching of Al appears to be as not affected by the converting process (cartridges have not a closed glass bottom) and consequently, if correctly applied, the described methodology results effective on the glass tube and on the cartridges in the same way.